Scada systems are usually centralised control systems designed to monitor and control an entire site in which most actions are controlled automatically by PLC. BeOne Campolongo project was described on this blog a few weeks ago, highlighting the competitive advantages and its integration into large scale processes.

Today, we would like to describe how Scada systems are developed at Arce Clima and the innovative solutions provided in various types of sectors: Let´s see our bespoke control solution at Gran Hotel Lugo.

The expertise of the Control Systems team

Before tackling a new project, the Control Systems team carry out meticulous research to assess the needs and control the setting conditions that need to be implemented. Arce Clima´s expertise and capabilities in the hospitality sector demonstrate that we have solutions for the challenges that might arise including control systems and environmental considerations.

Our management system identifies the most important aspect and project how monitoring/evaluation/data acquisition is going to be tackled. This technology allows end-users to have a truly open system to have the perfect fit for these type of applications in the HVAC environment.

Data can be assessed in quick and simple ways that the client surely will benefit from SCADA´s Systems to have more effective process controls.

CONTROL SYSTEMS AT EUROSTARS GRAN HOTEL IN LUGO

At the beginning of the year, a new HVAC installation was done at Eurostars Gran Hotel in Lugo. For the correct performance of such installation, Mitsubishi was the brand chosen to develop and control the Scada System.

The control systems utilise a PLC Setup that can be used with 5 expansion modules. Also, the project included a new efficient Generator Control System which has the operational capacity to sync all generators together.

The teams delivered the works while the venue was live an operational. HVAC equipment was integrated through two communication ports MODBUS RTU: 1 for the room area and the other one for the rest of equipment across the hotel. Specific works included:

- 5 Fan coils

- 1 heat recovery system, programmed to control the air quality at the living rooms with larger density of occupancy.

- 4 Mitsubishi VRV units at the kitchen area

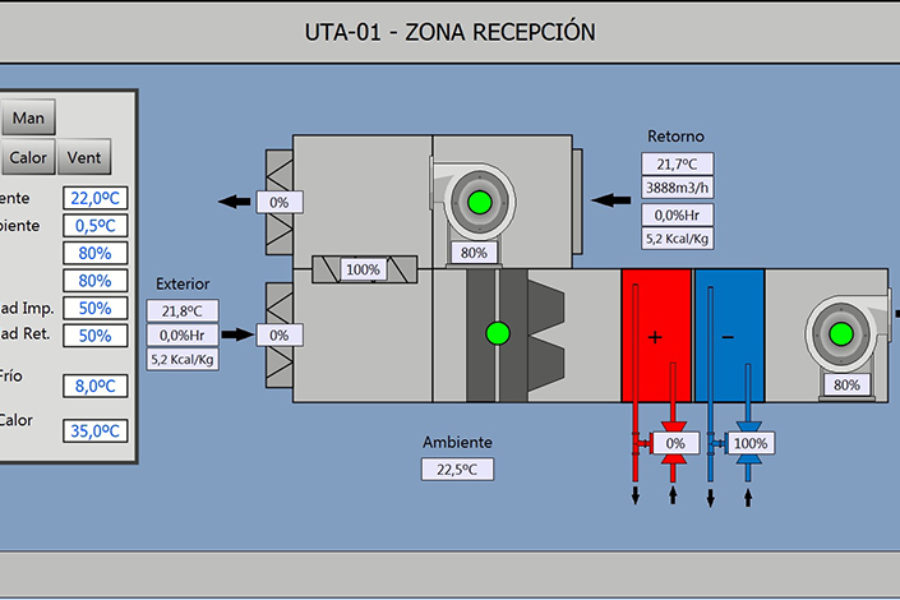

- 2 units for the air treatment with free-cooling at reception area. For the regulation of these 2 units, 2 controllers were installed at a machine level.

Climate control starts to operate when the guest opens the room with his card, allowing for temperature management at the thermostat. Although the automat limits the temperature range so the guest cannot set very high/low temperatures, avoiding unnecessary energy consumption. When the card is taken out, control systems automatically activate the 21 degrees Celsius pattern to search for the best thermal comfort.

For the correct supervision and control of all parameters and equipment, a Scada system was installed with remote access. Using the Scada system allows for a quick and open view of the control systems at each floor. One can also set different equipment parameters (schedules, temperatures, operation modes…etc). This not only provides with more energy efficiency but also more monitoring that the user can access through one click.

One of the most important aspects at the premises is the valve regulation and water circulating pumps. Due to facilities location, rooms are divided into north and south sector so the seasonal change applied in summer/winter is done automatically and independently for each zone at the Scada. Special attention is needed on programming correctly the pipework scheme with the current state of each valve and pump, being able to modify the necessary parameters to get the desired water temperature.

Visualization example

The project was under a stringent 12-month timeframe, requiring the team to develop innovative solutions to improve efficiency on site. With the implementation of Scada system to monitor pump flow, tank levels and leak detection, the completion of multiple levels concurrently was possible and satisfactory.

Ensuring maximum technology with Scada system has been very effective in its operation as well as on special requirements.